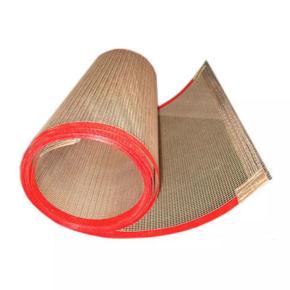

Other Industrial Belt

Silicone conveyor belt

Silicone conveyor belt

Silicone conveyor belt is a highly active adsorption material, belonging to amorphous substances. Insoluble in water and any solvent, non-toxic and odorless, chemically stable, and does not react with any substance except strong bases and hydrofluoric acid.

Various types of silicone gel form different micro-porous structures due to their different manufacturing methods. The chemical composition and physical structure of silicone determine that it has many characteristics that other similar materials cannot replace: excellent electrical insulation performance, aging resistance, chemical stability, high adsorption performance, good thermal stability, oxidation and weather resistance, radiation resistance, physiological inertness, good breath-ability, oil resistance, high and low temperature resistance, good electrical insulation performance, high mechanical strength, etc. Can be used for a long time at -160 ℃ to 360 ℃.

Silicone conveyor belts can be widely used as good electrical insulation sealing and liquid conveying materials in industrial sectors such as aviation, electronics, petroleum, chemical, mechanical, electrical, medical, oven, and food.

Advantage

1: Food grade, which is an important reason why it is used in the food industry;

2. High temperature resistance, conventional silicone tape can withstand high temperatures of 100-500 degrees Celsius, and its chemical properties are stable

3. Anti stick, silicone with non stick sugar, chocolate and other high sugar foods.

Good air permeability Silicone belt are made of high-temperature raw materials that have undergone high-temperature vulcanization, resulting in a large number of small pores inside. | |

| Surface non sticky Good surface non sticky. Smooth and textured surface with no burrs or burrs |

High temperature resistance good elasticity Can work continuously at a high temperature of 300 degrees without any qualitative changes, resistant to high temperature, compression, and good resilience | |

Disadvantage

1: Expensive, silicone belts are relatively expensive compared to ordinary conveyor belts;

2. The hardness is low, so some conveyor belts in the oven mostly use Teflon mesh belts/cloth;

3. Poor roll resistance, silicone belt lacks lateral stability, and the material is relatively soft.

INQUIRY

Categories

LATEST NEWS

CONTACT US

Contact:

Phone: 0086-15669710783

E-mail: echowlq@163.com

Whatsapp:0086-15669710783

Add: 9th Floor, Building 1, No.28, Henghe 3rd Road, Ouhai Economic Development Zone, Wenzhou City, Zhejiang, China.