Other Industrial Belt

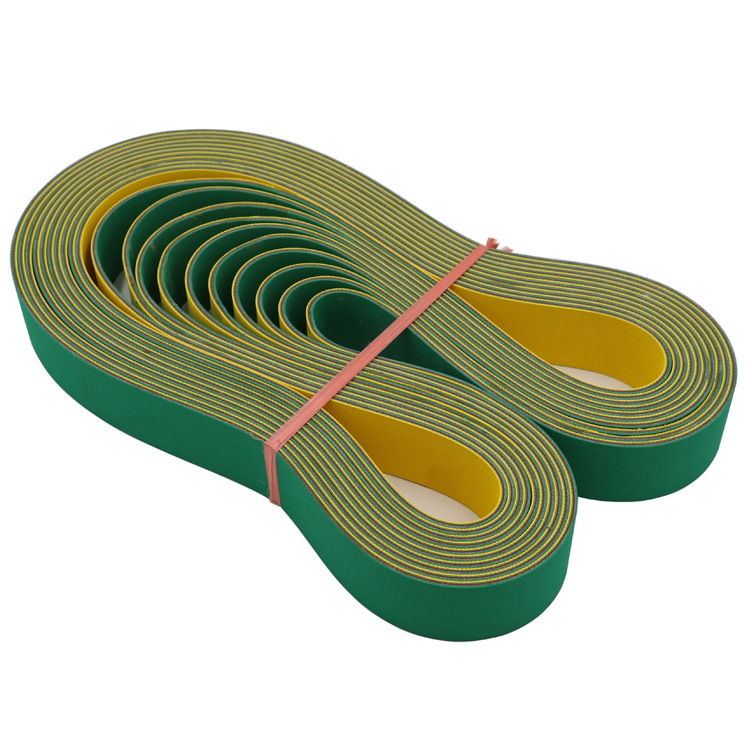

Textile Machine green yellow nylon Rubber TC Flat power transmission Belt

Flat Belts What are Flat Belts

Flat belts are power transmission belts that are flat and made of rubber, synthetic composites, or leather. They are used to transfer rotational power in industrial equipment and conveyor systems. Flat belts have a low profile with a positive grip, which makes them suitable for high-speed drive applications.

The design of flat belts consists of a flat cross-sectional shape with a trapezoidal profile that reduces slippage and improves power transmission efficiency. Flat belts are made of a combination of rubber and reinforcing fibers in sizes and strengths to meet the requirements of different applications.

here are several types of flat belts, including:

Rubber Belts

Rubber flat belts were originally introduced as a replacement for leather belts but were replaced by V-belts due to mistracking and problems with high tension. However, recent technological developments in the manufacturing of flat belts have made them more practical and cost-effective. In addition, they have high elasticity and offer excellent grip, making them suitable for high-speed and heavy-duty applications.

The rise in the use of flat belts is due to their excellent efficiency and low bending loss from their thin cross-section and low creep. Additionally, flat belts have less wear than V-belts and come in widths to fit any application.

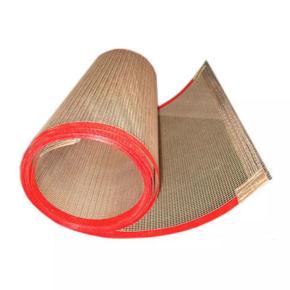

Fabric Cord Belts

Similar to fabric ply belts, but made with a single layer of fabric material that is reinforced with cords. The cords provide additional strength and stability to the belt, making them ideal for applications requiring high-tension loads.

Synthetic Flat Belts

Made with synthetic materials such as polyurethane or silicone, synthetic flat belts are known for their durability, flexibility, and resistance to wear and abrasion. Synthetic flat belts are used in a variety of industrial applications, including packaging, food processing, and power transmission.

In general, the choice between fabric ply, fabric cord, and synthetic flat belts will depend on the specific application requirements and operating conditions, such as load capacity, temperature, and exposure to chemicals.

Leather Belts

Leather belts were introduced during the first industrial revolution and were used through the end of the 19th and into the 20th century. They were replaced by flat rubber belts but are still used for some applications today and are available in one, two, or three ply. Leather belts have a smooth surface and are flexible, which makes them ideal for small diameter pulleys.

Thickness | color | Working temperature | tensile strength | 1% elongation | Minimum roller diameter |

1mm | Yellow green | -20/+100 | 120 | 3 | 15 |

1.5mm | Yellow green | -20/+100 | 180 | 5.5 | 25 |

2mm | Yellow green | -20/+100 | 200 | 5.5 | 25 |

2.2mm | Yellow green | -20/+100 | 250 | 10 | 25 |

2.5mm | Yellow green | -20/+100 | 250 | 10 | 25 |

3mm | Yellow green | -20/+100 | 250 | 10 | 30 |

4mm | Yellow green | -20/+100 | 300 | 10 | 30 |

5mm | Yellow green | -20/+100 | 300 | 12 | 40 |

INQUIRY

Categories

LATEST NEWS

CONTACT US

Contact: Jessie

Phone: 0086-15669710783

E-mail: echowlq@163.com

Whatsapp:0086-15669710783

Add: 9th Floor, Building 1, No.28, Henghe 3rd Road, Ouhai Economic Development Zone, Wenzhou City, Zhejiang, China.